Early May, I get a text from my daughter Grace, wanting to “spitball” about a project for Pride Month. Little did I suspect the enormity of the request.

Grace is an Art Director at Northern Ground, a terrific digital design studio in Milwaukee. Northern Ground’s super-cool office space is a renovated circa 1882 Scandinavian church and annex building in Walkers Point, the oldest neighborhood in Milwaukee. Located on Second Avenue, Northern Ground sits right along Milwaukee’s Pride Parade route. As a sponsor of the parade, Northern Ground was going to host a Pride Parade Party on their rooftop deck – a wonderful spot to celebrate and view the parade.

Celebrating Pride Month in a Fun and Joyful Way

Northern Ground wanted to contribute to the love and joy the Pride Parade brings to their city and display a Pride flag. As a matter of fact, Northern Ground wanted to celebrate Pride Month in a BIG way. They wanted a Pride flag large enough to hang from their rooftop deck rail and span the entire side of the annex building. Northern Ground’s Pride Flag would be a 40′ wide by 20′ high striped banner complete with all eleven colors of the Pride rainbow.

Like her mother, Grace is a Makeling. Although neither of us had ever sewn anything this large before, the pair of us did not even question our ability to get the flag made. We dove into the details to solve the foreseen challenges of such a monumental sewing project.

Workspace

Big Pride Flag requires a Big Workspace, and the Northern Ground basement was the place perfect for this task. Often used as a meeting room for brainstorming sessions with clients, the basement is a large, well-lit space. The wide expanse of polished concrete floor is very suitable for staging and laying out large swaths of fabric. The modular conference tables were an added boon, easily arranged to create one long work surface for measuring and sewing.

Materials Used

Fabric choice was crucial to success. Our flag needed to be lightweight and colorfast, yet strong enough to withstand the elements and be displayed for many Pride months. We settled on Ottertex® 1.9 oz. ripstop nylon from Fabric Wholesale Direct. This durable ripstop was available in in the array of colors needed, and the price suited the budget. For thread, I happened to have 8 spools of black, Coats & Clark UV Resistant Outdoor thread in my collection, which I was happy to donate to the cause.

Construction Methods

I arrived at Northern Ground on a bright and sunny Friday, my Pfaff Performance Icon in hand. Gracie brought her vintage Necchi machine, a trusty old workhorse. We were ready to sew.

Grace ordered seven yards of each Pride color for a total of 77 yards. The ripstop is 60″ wide, and cutting each color in half widthwise resulted in two, 30″W x 21’L stripes. After marking a cutting line, we used a hot knife fabric cutter to cut and seal the edges of the nylon in one go. Lucky for us, the polished concrete floor proved to be the perfect surface for this purpose.

Once the stripes were cut, we planned to sew the stripes together horizontally in two, eleven-stripe, 21′ long sections. Basically, Grace sewed one half of the flag, and I sewed the other. We figured a 3.5″ seam allowances plus 1.5″ double fold hems all around would get us close to the 40’w x 20’h finished dimension.

Focusing on sewing with precision to keep the stripes nice and straight, Gracie, Necchi, me and Pfaffie went to work. We each built a jig at 3.5″ on the decks of our machines to use as a guide for keeping the seam allowances straight and true.

Once the two halves were sewn horizontally, we could see there was a need to trim off ragged ends. In other words, we needed to make each half perfectly square before we could join the two halves together. This would be tricky.

By tying string taut between the structural columns in the basement, we created a giant T-square. We lined up the horizontal stripe along one string guide, and the shadow cast by the perpendicular string guide became our square cutting line. This bit of MacGyvered engineering resulted in two, almost perfectly square halves.

We joined the two halves with a vertical seam, pretty amazed at how neatly the stripes matched at center. The flag was so huge at this point, we needed to work as a pair getting the four sides hemmed, with Gracie acting as flag wrangler, and me guiding the edges into the machine.

Hanging & Securing

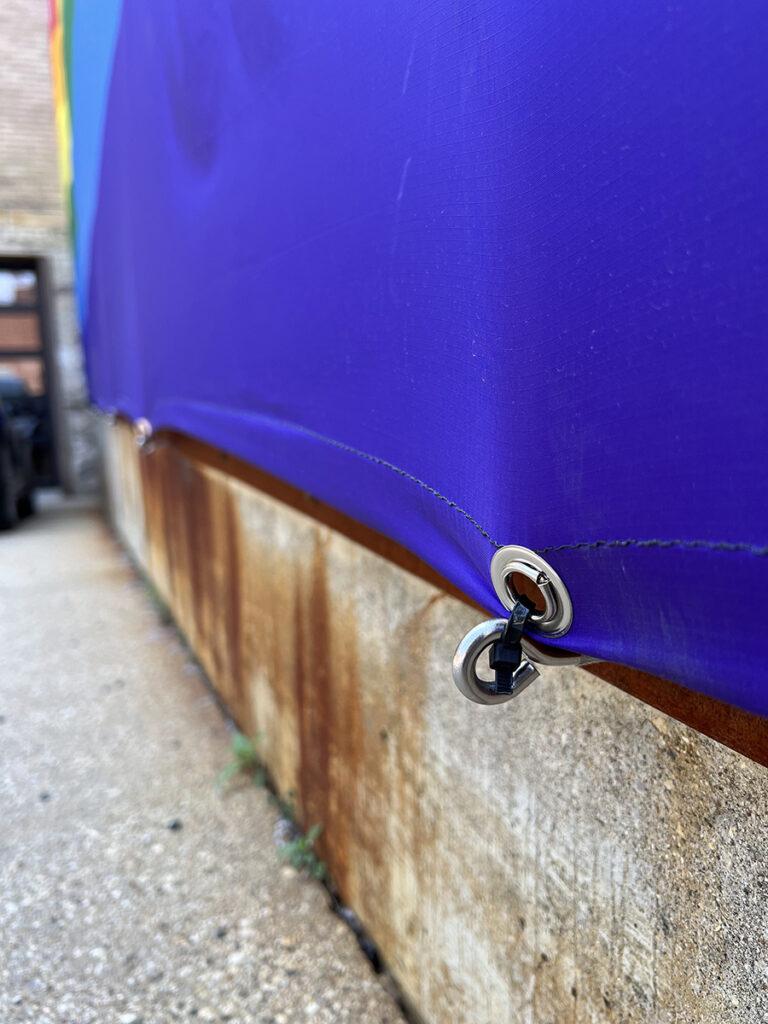

This was a huge piece of fabric to be whipping and bellowing in the breeze. As there was some concern about the weight and wind, a lot of thought was put into hanging and securing the flag in position. The flag was to be hung from the rooftop railing and draped over a wall clad in Corten steel panels. The Northern Ground crew installed grommets around the edges of the flag. Lashing straps were used along the top edge. Magnet hooks were used along the sides. The grommets along the bottom of the flag were secured to eyelets screwed into the siding.

So Proud of Our Pride Flag

I had a wonderful time collaborating with the Makelings at Northern Ground, and I am very proud to be involved in the make of this big celebratory symbol of equal rights, inclusion and the beauty of diversity.

Check out the Making of the Pride Flag Instagram Reel @makelingsmakethings @northernground

Amazing project! I am particularly impressed with the consideration given to every step from the making to the hanging. Terrific!